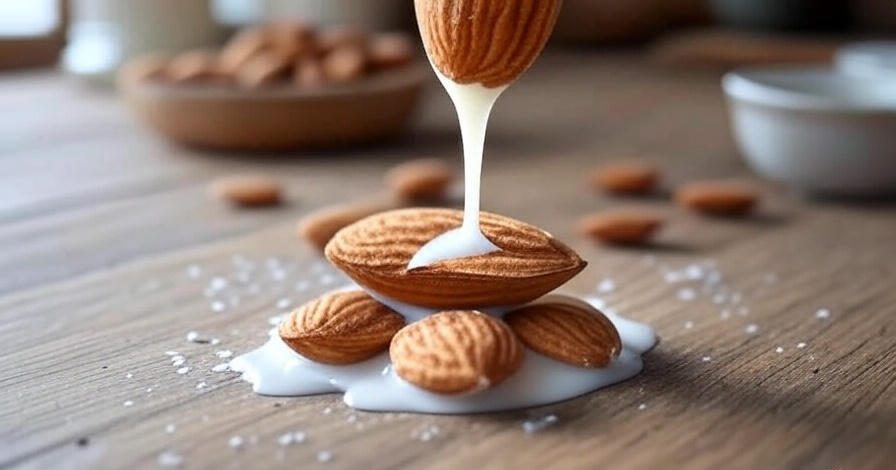

How Is Almond Milk Made?

Almond milk has become a household staple across America, with sales reaching billions of dollars annually. This creamy, nutty beverage offers a dairy-free alternative that appeals to vegans, lactose-intolerant individuals, and health-conscious consumers alike. But have you ever wondered exactly how manufacturers transform simple almonds into the smooth, white liquid that graces our coffee cups and cereal bowls?

The process of making almond milk involves several fascinating steps that combine traditional techniques with modern technology. From the initial soaking of raw almonds to the final pasteurization and packaging, each stage plays a crucial role in creating the product we know and love. This comprehensive guide will walk you through every aspect of almond milk production, both commercial and homemade methods.

The Foundation: Raw Almonds and Water

The journey begins with high-quality raw almonds. Commercial producers source these nuts from major almond-growing regions, primarily California’s Central Valley, which produces over 80% of the world’s almonds. The selection process focuses on uniformity, size, and freshness to ensure consistent flavor and texture in the final product.

Water quality proves equally important in almond milk production. Manufacturers use filtered, purified water to avoid any mineral content that might interfere with taste or shelf life. The water-to-almond ratio typically ranges from 3:1 to 4:1, depending on the desired richness and consistency of the final product.

Step One: Soaking the Almonds

The first step in almond milk production involves soaking raw almonds in water for 8 to 12 hours. This soaking process serves multiple purposes beyond simple hydration. The almonds absorb water and begin to soften, making them easier to blend and process. During this time, the nuts release enzyme inhibitors and phytic acid, which can interfere with nutrient absorption.

Commercial facilities use large stainless steel tanks filled with filtered water and precise amounts of almonds. Temperature control maintains the soaking environment between 60-70°F to prevent bacterial growth while allowing optimal hydration. Some producers add a small amount of salt to the soaking water, which helps break down the almond skins and improves the final texture.

Home cooks can replicate this process using a simple bowl and clean water. The almonds should be completely submerged, and the water may become slightly cloudy as compounds leach from the nuts. This cloudiness is normal and indicates that the soaking process is working effectively.

Step Two: Blanching and Skin Removal

After soaking, many commercial producers remove the almond skins through a process called blanching. Hot water or steam loosens the brown outer layer, allowing machines to strip away the skins efficiently. This step creates a whiter, smoother final product with a milder flavor profile.

The blanching process involves brief exposure to temperatures around 200°F, just enough to loosen the skins without cooking the almonds. Specialized equipment then uses friction and air pressure to separate the skins from the nuts. The removed skins don’t go to waste – they often become ingredients in other food products or animal feed.

Some artisanal producers skip this step, keeping the skins intact for a more rustic flavor and slightly beige color. The skins contain additional nutrients and fiber, though they can create a slightly grittier texture in the finished milk.

Step Three: The Blending Process

The heart of almond milk production lies in the blending stage. Commercial facilities use high-powered industrial blenders capable of processing hundreds of pounds of almonds per batch. These machines generate tremendous force, breaking down the softened almonds into tiny particles that will eventually become suspended in the liquid.

The blending process typically lasts 2 to 4 minutes, depending on the equipment and desired consistency. During this time, the almonds and water transform into a thick, creamy mixture resembling a smoothie. The goal is to achieve the finest possible particle size to create a smooth drinking experience.

Industrial blenders operate at speeds exceeding 20,000 RPMs, creating enough friction to heat the mixture slightly. This heat helps break down cell walls and release more flavor compounds from the almonds. Temperature monitoring ensures the mixture doesn’t overheat, which could damage nutrients or create off-flavors.

Step Four: Straining and Filtration

Once blending is complete, the mixture requires straining to remove larger particles and create the smooth texture consumers expect. Commercial producers use multi-stage filtration systems that progressively remove smaller and smaller particles.

The first stage involves coarse straining through mesh screens that catch any large almond pieces. This step removes chunks that might have escaped the blending process. The liquid then passes through finer filters, often made of specialized materials that trap particles while allowing the liquid to flow freely.

Professional filtration systems can remove particles as small as 10 microns, creating an incredibly smooth final product. The filtered solids, known as almond pulp, contain valuable nutrients and fiber. Many facilities dry this pulp to create almond flour or meal, minimizing waste in the production process.

Step Five: Fortification and Flavoring

Modern almond milk production includes fortification with vitamins and minerals to enhance nutritional value. Common additions include calcium carbonate, vitamin D2 or D3, vitamin B12, and vitamin E. These nutrients help almond milk compete nutritionally with dairy milk and address potential deficiencies in plant-based diets.

The fortification process requires precise measurement and mixing to ensure even distribution throughout the batch. Manufacturers add these nutrients in liquid or powder form, using specialized equipment to achieve uniform consistency. Quality control testing verifies that each batch meets nutritional labeling requirements.

Natural flavoring agents may also be added during this stage. Vanilla extract remains the most popular flavor addition, though producers also create chocolate, strawberry, and other varieties. Salt enhances the overall flavor profile, while natural sweeteners like cane sugar or monk fruit extract appeal to different consumer preferences.

Step Six: Homogenization

Homogenization prevents separation and creates the smooth, uniform texture that consumers expect from almond milk. This process forces the liquid through small openings under extreme pressure, breaking down fat globules and protein particles into microscopic sizes.

Commercial homogenizers operate at pressures between 2,000 and 4,000 pounds per square inch (PSI). The liquid passes through multiple stages, each designed to achieve specific particle sizes. This process ensures that the almond milk remains smooth and creamy without separating into layers.

The homogenization process also improves shelf life by creating a more stable emulsion. Smaller particles are less likely to clump together or separate over time, maintaining the product’s appearance and texture throughout its shelf life.

Step Seven: Pasteurization

Food safety requires pasteurization to eliminate harmful bacteria and extend shelf life. Commercial almond milk undergoes heat treatment using one of several methods, each designed to kill pathogens while preserving nutritional value and flavor.

High-Temperature Short-Time (HTST) pasteurization heats the almond milk to 161°F for 15 seconds. This method effectively destroys harmful microorganisms while minimizing nutrient loss and flavor changes. The liquid then cools rapidly to prevent overcooking.

Ultra-High Temperature (UHT) processing heats the milk to 280°F for 2-3 seconds, creating shelf-stable products that don’t require refrigeration until opened. This method allows for longer storage and distribution to distant markets.

Step Eight: Packaging and Quality Control

The final stage involves packaging the finished almond milk in various container types. Most commercial products use cartons made from paperboard with plastic linings, though some brands opt for glass bottles or plastic jugs. The packaging process occurs in sterile environments to prevent contamination.

Automated filling machines dispense precise amounts of almond milk into containers, which then receive sealed caps or closures. Each container gets date codes and lot numbers for traceability. Quality control testing throughout the process ensures consistency in taste, texture, and nutritional content.

Homemade Almond Milk Production

Creating almond milk at home follows similar principles but uses simpler equipment. The process begins with soaking one cup of raw almonds in three cups of water overnight. After draining and rinsing, the almonds blend with fresh water in a high-speed blender for 60-90 seconds.

Straining through cheesecloth or a nut milk bag removes the pulp, leaving smooth liquid behind. Home producers can add salt, vanilla, or sweeteners to taste. The resulting milk stays fresh in the refrigerator for 3-4 days, though it may separate naturally without commercial stabilizers.

Nutritional Benefits and Considerations

Almond milk provides several nutritional advantages over dairy milk, particularly for those with dietary restrictions. It contains fewer calories, no cholesterol, and significant amounts of vitamin E, a powerful antioxidant. The fortification process adds calcium and vitamin D, making it nutritionally comparable to dairy milk in these areas.

However, almond milk contains less protein than dairy milk, typically providing only 1-2 grams per serving compared to 8 grams in cow’s milk. The fat content is also lower, which affects the absorption of fat-soluble vitamins. These factors make almond milk suitable for some dietary needs but not others.

Environmental Impact of Almond Milk Production

Almond milk production has environmental implications that consumers increasingly consider. Almond trees require significant water resources, with each nut requiring approximately one gallon of water to produce. California’s frequent droughts have raised concerns about the sustainability of large-scale almond farming.

However, almond milk still uses less water overall than dairy milk production when considering the entire lifecycle. Dairy farming requires water for drinking, irrigation of feed crops, and processing, totaling significantly more water per gallon of milk produced.

Commercial vs. Artisanal Production Methods

Large-scale commercial production emphasizes efficiency, consistency, and shelf stability. These facilities can process thousands of gallons per day using automated systems and strict quality controls. The products reach wide distribution networks and maintain consistent taste and texture.

Artisanal producers focus on smaller batches with premium ingredients and unique flavor profiles. These operations often use traditional methods, local sourcing, and minimal processing. The resulting products may have shorter shelf lives but offer distinctive tastes and support local economies.

Innovation in Almond Milk Production

The almond milk industry continues evolving with new technologies and techniques. Some producers experiment with different almond varieties to create unique flavor profiles. Others explore fermentation processes that enhance nutritional value and digestibility.

Sustainable packaging solutions address environmental concerns, with some companies developing compostable containers or returnable glass bottles. These innovations reflect growing consumer awareness of environmental issues and demand for sustainable products.

Storage and Shelf Life

Proper storage extends almond milk’s shelf life and maintains quality. Refrigerated products typically last 7-10 days after opening, while shelf-stable versions can remain fresh for months before opening. Once opened, all almond milk requires refrigeration and should be consumed within a week.

Signs of spoilage include sour odors, curdling, or separation that doesn’t remix with shaking. These indicators suggest bacterial growth or breakdown of the product’s stability. Consumers should always check expiration dates and trust their senses when evaluating freshness.

The Future of Almond Milk

As plant-based diets gain popularity, almond milk production will likely expand and evolve. New processing techniques may improve nutritional profiles while reducing environmental impact. Consumer preferences will drive innovation in flavors, textures, and packaging options.

The industry faces challenges from other plant-based milk alternatives, including oat, pea, and hemp milk. Competition will encourage continued improvement in taste, nutrition, and sustainability. Regulatory changes may also affect production methods and labeling requirements.

Conclusion

The transformation of almonds into creamy, nutritious milk involves a complex process that combines traditional techniques with modern technology. From the initial soaking of raw nuts to the final pasteurization and packaging, each step contributes to the quality and safety of the finished product.

Understanding how almond milk is made helps consumers make informed choices about their dietary options. Whether produced commercially or at home, almond milk offers a versatile, plant-based alternative that satisfies various nutritional needs and preferences. As the industry continues to evolve, we can expect even better products that balance taste, nutrition, and environmental responsibility.

The journey from almond to milk demonstrates human ingenuity in food production and our ability to create delicious, nutritious alternatives to traditional products. As more people embrace plant-based diets, almond milk will undoubtedly remain a popular choice for years to come.